Sandwich panel

Contents |

[edit] Introduction

Sandwich panels, also referred to as metal composite material (MCM), metal composite panels (MCP), aluminium composite materials (ACM), insulated metal panels, structural insulating panels (SIP) and a few other terms, essentially consist of two layers of a rigid material bonded (often metallic but also engineered timber) to either side of a lightweight core (often a blown insulant but also mineral wool and other materials). The three components act together as a composite; that is, the combination of the characteristics of the components results in better performance than would be possible if they were acting alone.

The lightweight core keeps the two faces in the correct position, resists shear forces, and provides insulation, while the two faces provide durability, weather and impact resistance, and resist in-plane forces of tension and compression. In general the term sandwich panel is associated with thicker products used in the installation of single layer wall systems (sometimes referred to as insulated metal panels), but the term can also refer to thinner products manufactured for use in rainscreen systems (such as metal composite material panel systems).

Sandwich panel systems include the panels themselves (made up of formed outer and inner layers and the core material of differing thicknesses), the joints between them, fixings (often concealed) and a support system, differing depending on the whether a single layer system or a double layer rainscreen and detail designs.

[edit] History and development

Composite cladding systems have been in use for a considerable time, in particular for the manufacture of vehicles such as trains and planes, but the development of advanced sandwich panels for cladding buildings first began in the 1930’s, when they were researched by organisations such as the Forest Products Laboratory, and used by architects including Frank Lloyd Wright. They went on to become increasingly popular following the second world war.

Modern sandwich panels can be flat, bent, curved and joined together in an almost unlimited range of configurations and are available in a wide variety of colours, finishes, thicknesses, edge details and profiles depending on performance requirements.

They are generally fabricated off-site and are particularly useful where a high-performance cladding is required, with good structural strength, a high level of insulation and low weight.

[edit] Uses

Sandwich panels are widely used as an external cladding for single and multi-storey buildings, where they are required to provide weather resistance, and resistance to wind-loading, access loads, self-weight and so on. However, they are also used to create insulated internal envelopes, ceiling panels, partitions (for example in cold stores) and for fire-resisting compartment walls.

Building types that commonly feature sandwich panels include:

- Industrial buildings and processing plants.

- Temporary buildings.

- Storage buildings.

- Clean rooms.

- Agricultural buildings.

- Shopping centres.

- Sports facilities.

- Transport buildings.

[edit] Materials

The outer faces of sandwich panels are most commonly made of metals such as:

However, other materials that can be used include:

- Precast concrete, sometimes clad with other finishes such as brick.

- Cement board.

- Glass fibre reinforced polypropylene.

- Poly vinyl chloride (PVC).

- Magnesium oxide board (MgO).

- Plywood.

- Oriented strand board (OSB).

- Glass reinforced plastic (GRP).

Cladding systems typically include a rigid polyurethane core, but other core materials include:

- Expanded polystyrene (EPS).

- Extruded polystyrene (XPS).

- Mineral wool (rock fibre) (MWRF).

- Modified Phenolic foam (MPHEN).

- Polyisocyanurate (PIR).

- Folded metal, paper, aramid and carbon fibres. See Foldcore for more information.

- Honeycomb materials (such as Polypropylene).

[edit] Properties

Sandwich panels can be selected because of their:

- Ease and speed of installation.

- Rigidity.

- Thermal, fire and sound insulation.

- Airtightness

- Robustness and durability

- Low maintenance / cleaning requirements.

- Low capital cost.

- Low lifetime costs

- Chemical and biological resistance

- Light weight.

- Weather resistance.

- Dimensional stability.

- Availability as standard products off-the-shelf.

However, There can be particular difficulties associated with buildings containing combustible sandwich panels. For more information see Fire performance of sandwich panel systems, Association of British Insurers, May 2003.

[edit] Related articles on Designing Buildings

- Building fabric.

- Cladding.

- Composites.

- Curtain wall systems.

- Foldcore.

- Glazing.

- Insulated metal panel.

- Metal composite panels.

- Metal composite material panel systems MCM and MCP.

- Metal profile cladding.

- Polyurethane spray foam in structurally insulated panels and composite structures.

- Precast concrete cladding.

- Rainscreen.

- Structural Insulated Panels.

- Wall types.

- Weatherboarding.

Featured articles and news

Delivering radical reform in the UK energy market

What are the benefits, barriers and underlying principles.

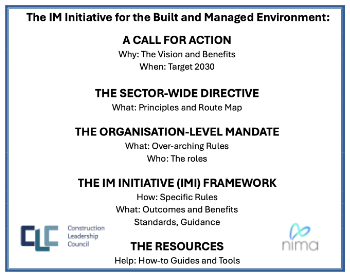

Information Management Initiative IMI

Building sector-transforming capabilities in emerging technologies.

Recent study of UK households reveals chilling home truths

Poor insulation, EPC knowledge and lack of understanding as to what retrofit might offer.

Embodied Carbon in the Built Environment

Overview, regulations, detail calculations and much more.

Why the construction sector must embrace workplace mental health support

Let’s talk; more importantly now, than ever.

Refurbishment for net zero; the BSRIA white paper

The everyday practice of tackling energy efficiency, fabric first, ventilation, air quality, and occupant wellbeing.

Sustainable construction design teams survey

Shaping the Future of Sustainable Design: Your Voice Matters.

Ensuring the trustworthiness of AI systems

A key growth area, including impacts for construction.

Foundations for the Future: A new model for social housing

To create a social housing pipeline, that reduces the need for continuous government funding.

Mutual Investment Models or MIMs

PPP or PFI, enhanced for public interest by the Welsh Government.

Stress Awareness Week ends but employer legal duties continue.

A call to follow the five Rs for the business and for the staff.

Key points and relevance to construction of meeting, due to reconvene.

Cladding remediation programmes, transparency and target date.

National Audit Office issue report on cladding remediation.

HBPT and BEAMS Jubilees. Book review.

Does the first Labour budget deliver for the built environment?

What does the UK Budget mean for electrical contractors?

Mixed response as business pays, are there silver linings?

Comments